WEBINAR

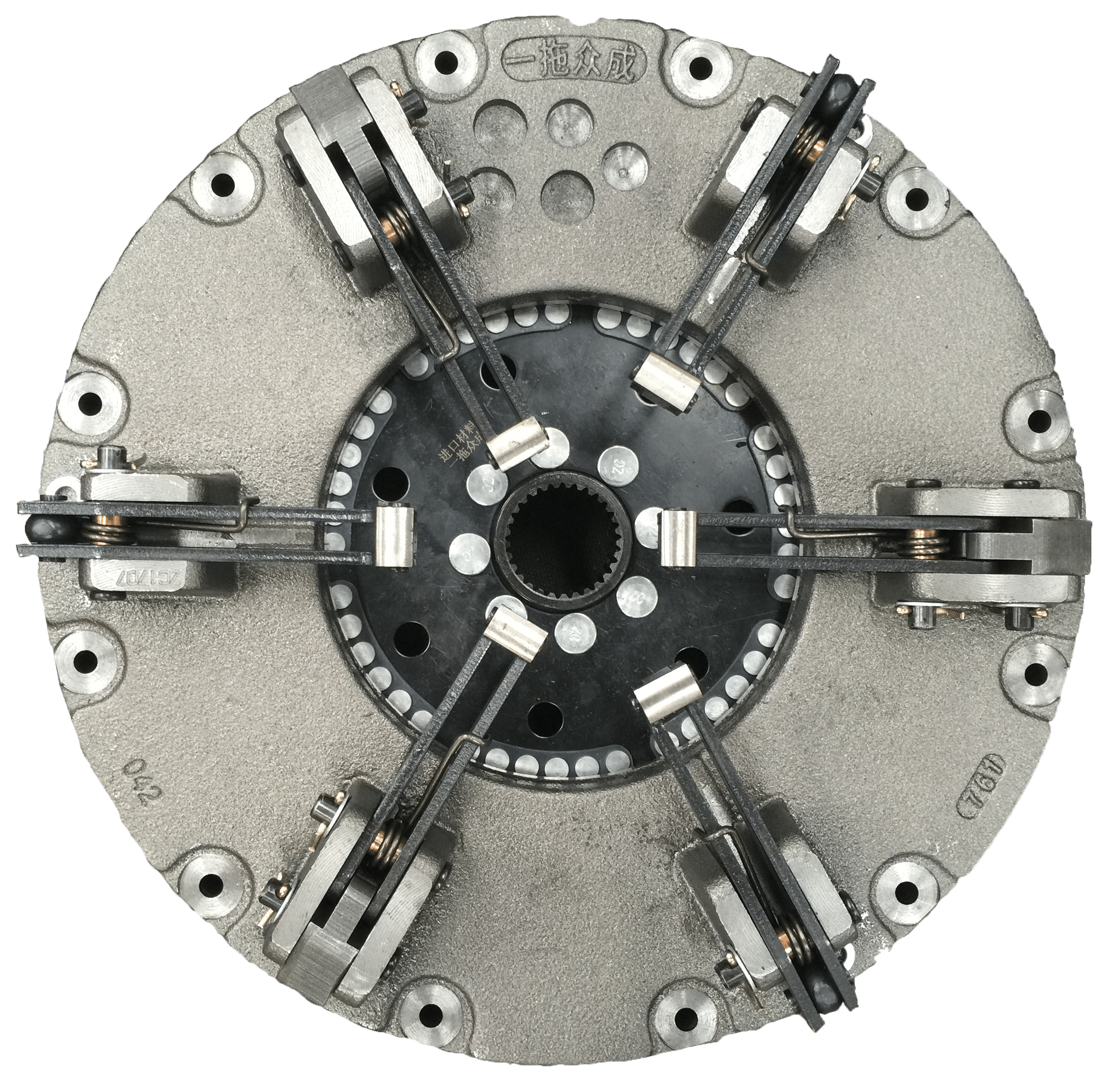

Clutch Disc

Learn More“ MIBA is an Austria-based multinational company founded in 1927 that focuses on the manufacture of mechanical components and industrial equipment. The company is one of the world's leading manufacturers of friction materials, mainly producing bearings, gears, transmission systems, engine parts and industrial equipment.MIBA is used in a wide range of industries including automotive, aerospace, construction machinery, heavy trucks, rail, energy and industrial sectors. ”

“ MIBA has been committed to R&D and innovation, and cooperates with the world's leading enterprises and institutions to develop advanced solutions and new technologies. ”

Through the cooperation with MIBA, we choose its friction materials with superior performance to provide our customers with higher performance and more reliable clutches.

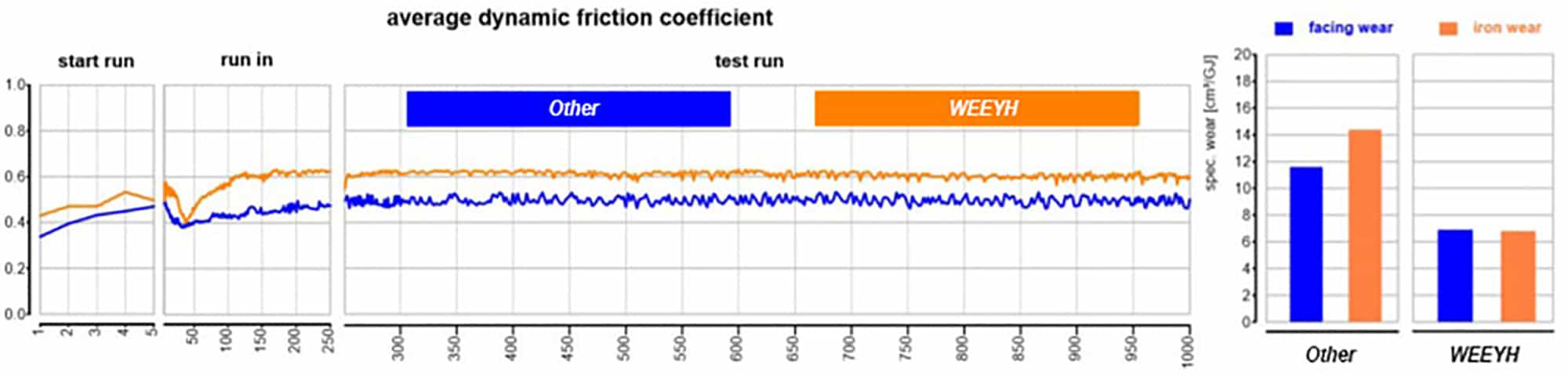

Our cooperation will enable us to fully understand the properties and differences of MIBA'S various materials, which will help us to accurately choose suitable products for our customers. Through this cooperation, we jointly conduct experiments to make friction materials and clutch pressure plate materials have a better match, these friction plates have a higher coefficient of friction and longer life. Our customers will benefit from our cooperation as they will get more reliable and durable clutch products.

WEEYH is jointly formed by China's top agricultural machinery parts factories, focusing on the R&D and production of agricultural machinery parts. About 200,000 sets of agricultural machinery related parts are produced by WEEYH'S factories and sent to the world every year.