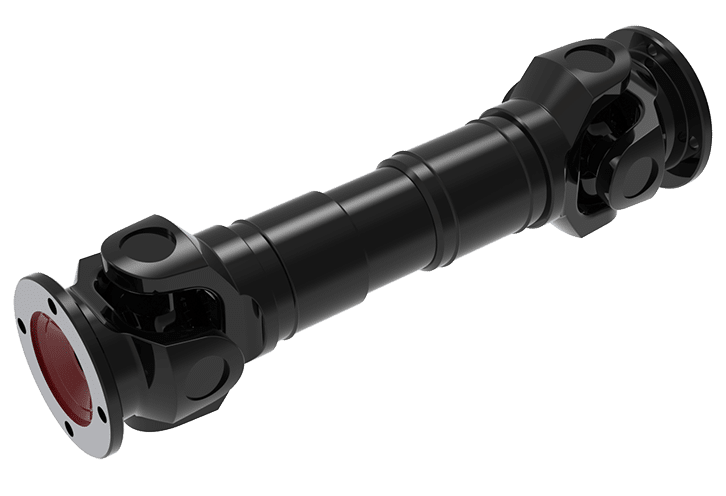

Car Cardan Shaft Series

WEEYH has rich technical expertise in the field of drive shafts. The WEEYH drive shaft team is composed of experienced engineers and technical experts with profound knowledge of drive shaft design and manufacturing. We constantly pay attention to industry trends and technological innovations to maintain a leading position in technology.

WEEYH focuses on innovative research and development, and continues to promote technological progress in the field of drive shafts. WEEYH continuously invests resources in R&D and innovation to develop new drive shaft technologies and solutions.

A driveshaft main function is to connect the engine and the drive wheel or transmission, and transmit the torque generated by the engine to the drive wheel or transmission to drive the vehicle or mechanical equipment.

The structure of the propeller shaft mainly includes the following components:

The choice of material for a propeller shaft usually depends on the field of application, requirements and expected performance.

Here are some common propeller shaft material options:

● Carbon Steel:Carbon steel is one of the common drive shaft materials, it has good strength and rigidity, it is usually used for medium load and low speed applications, suitable for most conventional vehicles and mechanical equipment.

● Alloy Steel:Alloy steels have high strength, rigidity and wear resistance, and are suitable for high-load and high-speed applications such as high-performance cars, trucks and construction machinery.

● Stainless Steel:Stainless steel is resistant to corrosion and oxidation and is suitable for applications requiring resistance to corrosion and high temperature environments.

● Aluminum Alloy:Aluminum alloy has light weight, good thermal conductivity and corrosion resistance.

● Carbon Fiber Composite:Carbon fiber composites have excellent strength and stiffness, while being lightweight and corrosion-resistant.

Material selection depends on several factors, including expected loads, rotational speeds, environmental conditions, cost, and the requirements of a particular application. Engineering analysis and testing are typically performed to determine the most appropriate material selection to ensure the drive shaft has the required strength, stiffness and durability.

In the production engineering of propeller shaft s, common detection methods and controls include the following aspects:

● size measurement: Dimensional measurements can be made by using measuring tools such as micrometers, calipers, projectors, coordinate measuring machines, etc.

● Material testing:Material testing may involve chemical composition analysis, metallographic structure observation, hardness testing, etc., to verify the strength, wear resistance and corrosion resistance of materials.

● Magnetic Particle Testing:The surface of the propshaft is inspected using magnetic particle testing methods to detect possible cracks, defects and fatigue damage.

● Dynamic balance test:For drive shafts that need to rotate at high speeds, a dynamic balance test is necessary.

● Fatigue Life Test:Fatigue life tests are performed on drive shafts by simulating fatigue loads and cycles under actual service conditions.

● Assembly inspection:Fatigue life tests are performed on drive shafts by simulating fatigue loads and cycles under actual service conditions, which can be performed on a test bench for continuous and cyclic loading to evaluate the durability and life of drive shafts during long-term use.

The above detection methods and control measures are designed to ensure the dimensional accuracy, material quality, structural integrity and performance reliability of the drive shaft. Through the detection and control of each link in the production process, the quality level of the propeller shaft can be improved and the needs and requirements of customers can be met.

For common models in the market, WEEYH will set up inventory and promise:

One Day: Order today, ship same day

One Pcs: MOQ 1pcs

WEEYH'S inventory usually contains a variety of common spare parts, as well as some rare spare parts.

WEEYH aims to ensure that you have access to the spare parts you need to repair and replace your agricultural machinery in a timely manner.