WEBINAR

Clutch Disc

Learn More

Torque Capacity: Driveshaft design needs to take into account the maximum torque transfer capability required. This depends on the power requirements of the vehicle or machinery and the range of torque.

Strength and Rigidity: The material selection and geometric design of the drive shaft should be of sufficient strength and rigidity to withstand torque and loads. This includes choosing the proper material, diameter and wall thickness, etc.

Symmetry and Balance: Driveshaft symmetry and balance are critical to reducing vibration, reducing noise and improving transmission efficiency. The symmetry and balance of the shaft section should be considered in the design.

Vibration and Shock Absorption: Mechanisms such as flexible shafts or elastic couplings can be used to absorb vibration and shock in the drive shaft system, thereby reducing the impact on other components.

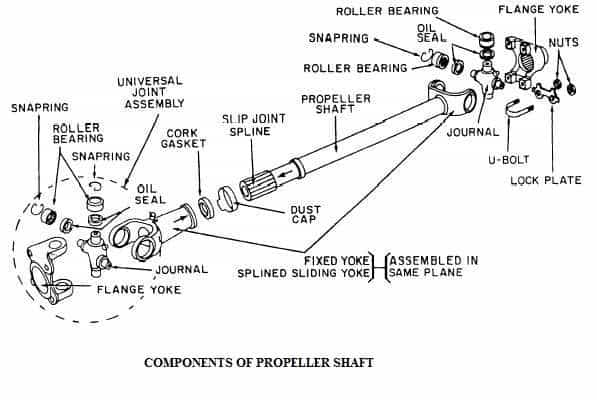

Shaft Section Support and Bearings: The shaft section support and bearing selection of a drive shaft is critical to shaft stability and smooth running. Proper bushings and bearings reduce shaft bending and vibration.

Shaft connection: The shaft connection method of the drive shaft is also part of the design consideration. Common connection methods include bolt connections, keyway connections, and welding.

Lubrication and cooling: The design of the drive shaft also needs to consider the lubrication and cooling system to ensure the lubrication and temperature control of the shaft section.

These design considerations are important in both the design and manufacture of drive shafts. It is necessary to select the appropriate design scheme according to the specific application needs, power requirements and system requirements, and ensure that the drive shaft meets the relevant standards and specifications.

WEEYH is jointly formed by China's top agricultural machinery parts factories, focusing on the R&D and production of agricultural machinery parts. About 200,000 sets of agricultural machinery related parts are produced by WEEYH'S factories and sent to the world every year.

We have a top testing laboratory, from material analysis to finished product inspection, each link has a corresponding testing process. More than 30 kinds of testing equipment have built the guarantee of WEEYH safety.