WEBINAR

Clutch Disc

Learn More

A clutch is a mechanical device used to connect and disconnect power in a transmission system. Its main function is to transmit or interrupt power between the engine and the transmission, enabling the vehicle or machinery to start, shift and stop.

The working principle of the clutch is based on the action of friction and pressure. Normally, the clutch is engaged, transferring power from the engine to the transmission. When shifting gears, stopping or idling the engine, the clutch can be disengaged to separate the engine from the transmission and no longer transmit power.

Here is a detailed explanation of how the clutch works:

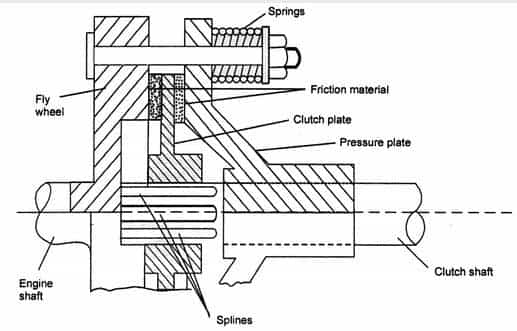

Flywheel: The output shaft of the engine is connected to a large rotating disc called the flywheel. The purpose of the flywheel is to store the moment of inertia of the engine and provide a smooth connection point.

Pressure Plate and Separator: A clutch has two main parts, the pressure plate and the separator. The pressure plate is connected to the flywheel by a spring, and the separator is connected to the input shaft of the transmission.

Friction material: Between the pressure plate and the separator, there is a layer of friction material (usually a friction plate or a combination of friction plates), which tightly contacts the pressure plate and the separator through pressure. This friction material can transmit power and has a certain coefficient of friction.

Pressure device: The clutch also includes a pressure device, which applies pressure to the pressure plate through a set of springs or a hydraulic system. This pressure brings the friction materials into tight contact, which transmits power.

When the clutch is engaged:

When the driver depresses the clutch pedal, the pressure device decreases or disappears, so that the pressure plate is separated from the separator.

After the pressure plate is separated from the separator, the friction force between the friction materials is reduced, and the power of the engine is no longer transmitted to the transmission device.

This allows the driver to change gears or bring the vehicle to a stop without placing excessive load on the transmission.

When the clutch is disengaged:

When the driver releases the clutch pedal, the pressure device reapplies the pressure, so that the pressure plate and the separator are in tight contact again.

After the pressure plate is in contact with the separator again, the friction force between the friction materials increases, and the power of the engine is transmitted to the transmission again.

So that the vehicle or machinery can continue to move.

The working principle of the clutch allows the driver to control the power transmission of the engine to achieve smooth shifting, starting and stopping operations. At the same time, the clutch also protects the transmission and the engine, since they are no longer subject to interacting forces when the clutch is disengaged.

WEEYH is jointly formed by China's top agricultural machinery parts factories, focusing on the R&D and production of agricultural machinery parts. About 200,000 sets of agricultural machinery related parts are produced by WEEYH'S factories and sent to the world every year.

We have a top testing laboratory, from material analysis to finished product inspection, each link has a corresponding testing process. More than 30 kinds of testing equipment have built the guarantee of WEEYH safety.