WEBINAR

Clutch Disc

Learn More

In ships and airplane, common drive shaft applications are as follows:

Ship

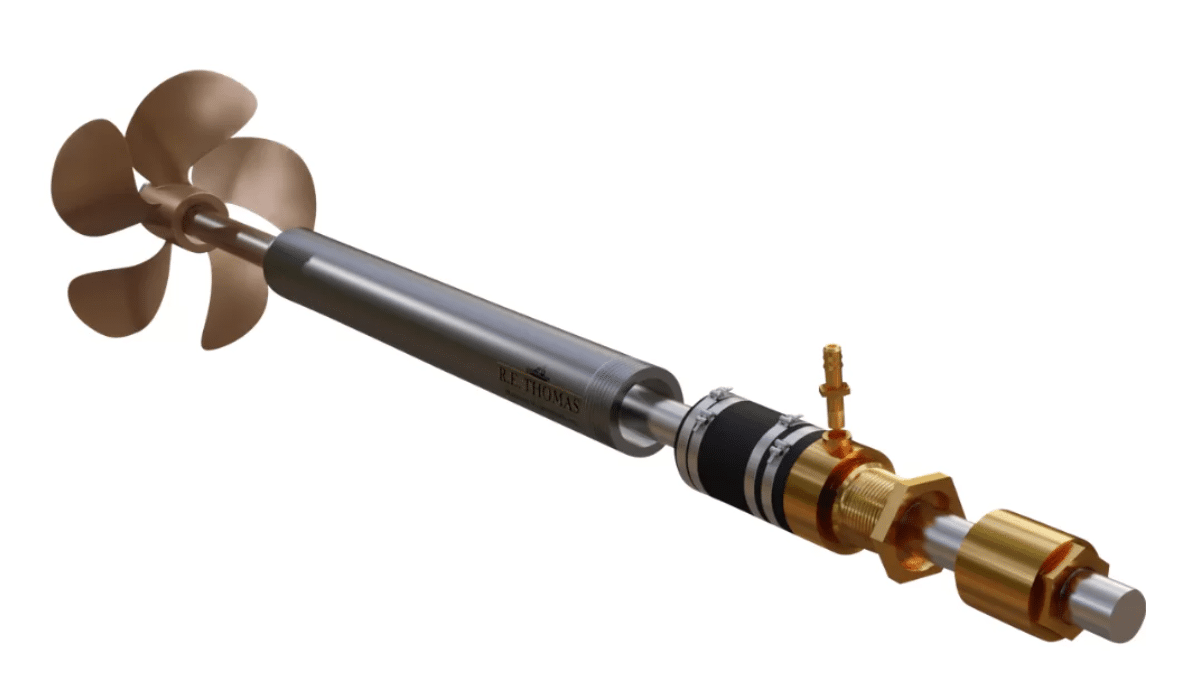

Main propulsion system: The main propulsion system of a ship usually uses a drive shaft to transmit power from the engine to the propeller or hydrodynamic jet to propel the ship forward. These drive shafts are usually hollow shafts or hollow cylindrical shafts with sufficient strength and corrosion resistance to handle the harsh marine environment.

Ship auxiliary equipment: the drive shaft is also used to transmit power to the ship's auxiliary equipment, such as generators, pump stations, compressors, fire pumps, etc. These drive shafts are usually suitable for small and medium power applications and are designed and selected according to the working needs of specific equipment.

Airplane

Engine drive system: In some aircraft, the drive shaft is used to transmit engine power to the aircraft's propulsion system, such as a propeller or jet engine. These drive shafts are usually lightweight designs that require high strength and vibration resistance to accommodate high-speed rotation and complex working conditions.

Auxiliary Power Unit (APU) transmission system: The APU on an aircraft usually uses a drive shaft to transmit power to auxiliary equipment, such as power generators, hydraulic pumps, air sources, etc. These drive shafts need to meet the requirements of high-speed rotation, light weight and high reliability.

It should be noted that in ships and aircrafts, the design and selection of the drive shaft should take into account the special working environment and performance requirements, such as corrosion resistance, light weight, high reliability and safety, etc. In addition, the drive shafts of ships and aircraft also need to comply with the corresponding industry standards and regulations to ensure their safety and reliability during operation.

WEEYH is jointly formed by China's top agricultural machinery parts factories, focusing on the R&D and production of agricultural machinery parts. About 200,000 sets of agricultural machinery related parts are produced by WEEYH'S factories and sent to the world every year.

We have a top testing laboratory, from material analysis to finished product inspection, each link has a corresponding testing process. More than 30 kinds of testing equipment have built the guarantee of WEEYH safety.